Potable water treatment

What is potable water?

Potable water is water which is safe to drink. It must be safe in terms of chemical composition and organoleptic properties. Usually, potable water comes from surface or underground water, which will then need be treated to levels that meet the local standards for consumptions. Access to safe potable water is essential for everyday life, thus it’s important to ensure the quality of water from the water treatment plant to the delivery point.

What is potable water treatment?

To ensure potable water meets the required standard, it’s essential that the water goes through appropriate treatment before delivery.

The conventional method for treating surface water involves transferring water from a lake, reservoir, or river into a series of tanks for coagulation, flocculation, and clarification. In particular, the clarification step is where the heavy particles (flocs) settle to the bottom and the resulting clear water is sent to filtration steps. In order to remove even the smaller particles, the clarified water passes through layers of sand, and gravel. Eventually, charcoal is used to remove any soluble organics and/or adsorbable pollutant. After that, a little amount of chlorine or an UV lamp is added to kill any residual germ or microbe present in the water and to ensure residual coverage within the water distribution network.

Compared with the conventional method of water treatment processes, where the quality of treated water varies with the quality of feed water, membrane filtration is capable of producing water of consistent quality regardless of the source. Beyond that, PCI Membranes’ tubular and spiral-wound membrane solutions are the best choice for this application due to the following advantages:

- Cost saving (compared with the traditional technologies, membrane filtration lowers chemical costs, waste disposal costs, operating and maintenance costs);

- Does not generate sludge and maintains a high quality of treated water in spite of both sudden and substantial changes in raw water quality;

- In case of using our tubular membranes, they can be cleaned mechanically with special designed foam balls, which reduces needs for a CIP cleaning step to once per quarter, subject to feed water quality.

Potable water treatment process with membranes

Membrane filtration is an important stage in potable water treatment. The aim of a membrane filtration system is to remove unwanted substances from water using microfiltration, ultrafiltration, nanofiltration, or reverse osmosis.

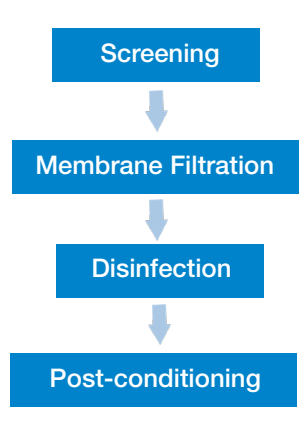

Potable water treatment processes based on membrane filtration are divided into 4 steps: screening, membrane filtration, disinfection (chlorination) and post conditioning (remineralisation).

First of all, the raw water goes through screening, where the bulk of suspended solid is removed.

Next, membrane filtration is used to retain the contaminants (such as colloidal particles, pathogens, organics, colour, suspended solids, salts, etc.), whilst allowing clean water to flow through. Our C10 Series modules are the ideal choice for this step, due to their ability to handle suspended solids without blocking of membrane tubes. Whenever low suspended solids contents are present, our Spiral-Wound membrane elements are the most cost-effective solution, but require more advance pre-treatment processes in comparison to the C10 Series.

After water has been filtered, there will be post-conditioning and disinfection. A disinfectant may then be added in order to ensure that pathogens won’t grow in the distribution network

How can we help you?

Do not hesitate to contact our experts who will work with you to conduct project assessments, run a pilot test, customise, design and install your membrane filtration system, which best fits your needs.

Our membrane water treatment solutions

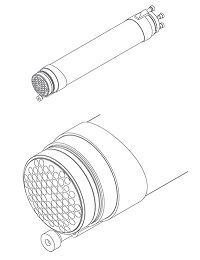

Our C10 tubular series modules and their nominal 12.7–mm diameter tubular UF or NF membranes are utilised in the Fyne process due to their ability to handle suspended solids without plugging.

The raw water is divided into two streams on the basis of molecular weight by passing it over a semi-permeable membrane. When pressure is applied to the water, the semi-permeable membrane allows the passage of a proportion of the water and smaller molecules, referred to as Permeate (or Filtrate), but retains the larger molecules in the solution, referred to as Retentate (or Concentrate). We are using very tight UF membranes (2 kDa and 4 kDa) to decolourise, and remove other components such as organic carbon, pathogens, metals, suspended solids and others, from the raw water source. As the process’ waste stream is simply concentrated raw water, there are no environmental concerns to prevent its discharge back to the local water body.

Our FG-SpiraCore™ Dura-Cl-NF membrane elements are made from Polysulfone (PSO) and are offered with 1,000 Da or 500 Da cut off. These Spiral-Wound NF membrane elements can effectively remove endocrine disruptors, antibiotics, disinfection by-product precursors and trace organic pollutants in water, and can retain some minerals. The used membrane material has resistance to free chlorine in operation is less 10 ppm, but for short running it could even up to 100 ppm. The single-stage recovery is up to 90% and the system recovery is up to 98%, which is more than 15% higher than the traditional Spiral-Wound RO membrane elements. And the operating pressure is 0.3-0.7 MPa, more than 30% lower than the traditional RO membrane – subject to specific application.