TUBULAR MEMBRANES

TUBULAR MEMBRANES

PCI Membranes (a Filtration Group® brand) is a world leader in the custom-built crossflow membrane filtration systems for liquid separation using membrane technology and has been manufacturing membranes and membrane systems for more than 50 years supplying worldwide markets.

Our open-channel membranes have the advantage of resistance to blocking and fouling by suspended or precipitate matter, with consequent minimal pretreatment requirements and ease of cleaning (PCI Membranes’ mechanical sponge-ball cleaning offers an alternative to chemical cleaning). With our broad product portfolio, we select the most appropriate membrane type to suit each application, minimising investment and running costs and maximising your benefits.

On this page, you will find an overview of our tubular membrane solutions, which covers A Series Tubular Membrane Modules, B1 Series Tubular Membrane Modules, C10 Series Tubular Membrane Modules, and Classic Series Tubular Membranes & Modules.

To learn more about the features, specifications, and fields of the application, please click on the button below the product. If you have any questions, please contact us.

A SERIES TUBULAR MEMBRANE MODULES

A Series tubular module incorporates a robust, low cost module in stainless steel AISI housing for A5, A19 and A37 modules or GRP for A8 modules, together with a choice of tubular membranes in various molecular weight cut-off range.

The open channel design enables you to process liquids with high levels of suspended solids without plugging and facilitates highly effective cleaning in place. The compact design gives the module a high mechanical strength allowing operating pressure of 7 to 10 bar subject to tube diameter. Read More

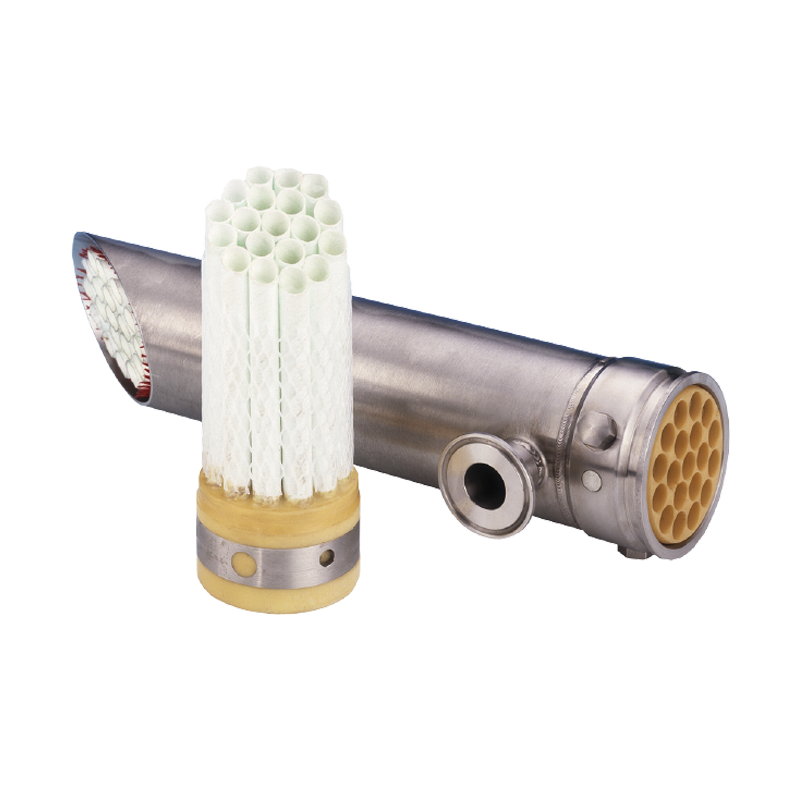

B1 SERIES TUBULAR MEMBRANE MODULES

B1 Series tubular modules provide you with a robust module and a wide range of fully interchangeable membrane elements. Its design allows you to replace the membranes with ease and at a low cost. Each B1 module comprises 18 perforated stainless steel tubes in the form of a shell and tube, each tube fitted with a membrane element. The flow of the process fluid through each of the tubes is controlled by specially designed end caps connecting either all 18 tubes in series or dividing the 18 tubes into 2 pathways of 9 tubes in series or feeding all 18 tubes in parallel. High levels of suspended and colloidal materials can be tolerated. The design is free of dead spaces, which reduces the fouling potential of the membranes while ensuring maximum effectiveness of cleaning-in-place procedures. Read More

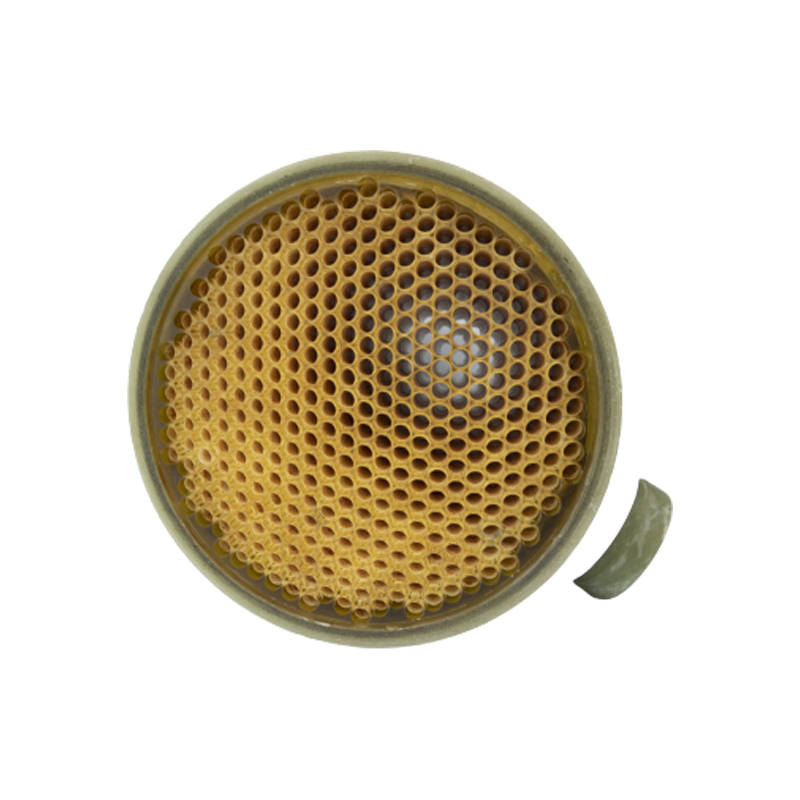

C10 SERIES TUBULAR MEMBRANE MODULES

C10 Series tubular module consists of a housing containing a bundle 72 perforated ABS tubes. The tight tubular UF membranes or tubular NF membranes are inserted into these tubes. The membranes are sealed into the tubes by rubber tubes seals, and then the tubes are connected by U bends plugged into the tubes seals. This provides a continuous hydraulic path through all 72 tubes in series. Modules are usually mounted in parallel in arrays called stacks. For each stack, pipework may be provided to distribute the feed fluid to the C10 modules, and collect concentrate and permeate from the C10 modules. Read More

CLASSIC SERIES TUBULAR MEMBRANES & MODULES

PCI Membranes’ classic tubular modules are well suited to handle aqueous feeds with high levels of dry substances, high viscosities, or high degrees of fouling. Classic products are available in a wide range of tubular Ultrafiltration and Reverse Osmosis membranes. They are constructed in plastic housings and offered in three lengths (2m, 3m and 6m). Read More